About Testing

As an engineering bearing factory, we are committed to using the most advanced international technologies to ensure product quality. We are equipped with top international metrology, material testing, physical and chemical testing, bearing testing, and monitoring equipment, and have introduced an online detection and analysis system to ensure precision at every stage.

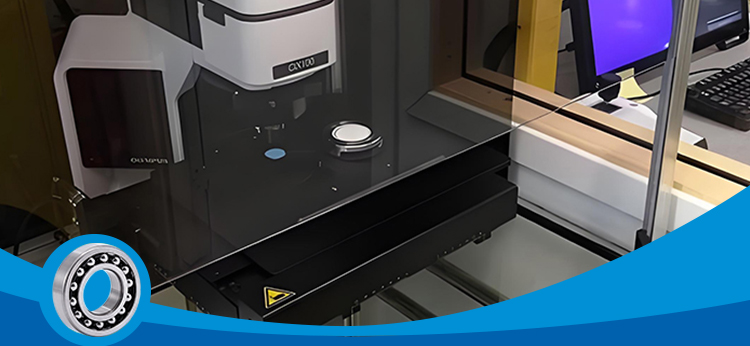

In addition, we also have domestic leading three-coordinate measuring instruments, length measuring instruments, Hommel roundness measuring instruments, and other high-precision detection equipment, as well as international well-known brand equipment such as German microhardness testers, Japanese metallographic microscopes, and contour measuring instruments. The application of these advanced devices not only improves our detection efficiency but also ensures the excellent stability of product quality.

Through these high-precision detection devices, we strictly control the production process to provide customers with more reliable and high-quality bearing products.

Bearing-related testing processes

Size accuracy testing

Surface quality testing

Hardness testing

Rotation accuracy testing

Clearance testing

Vibration and noise testing

Material and metallographic testing

Lubrication testing

Service life and durability testing

Sealing performance testing

Cleanliness testing