Superior Bearing Alternative -The Superior Alternative

Providing the most reliable bearing solutions, Rangyun ceramic bearings feature corrosion resistance and wear resistance

Ceramic Bearing Product Parameters

Ceramic bearings are mainly made of ceramic materials such as silicon nitride, zirconia, alumina and silicon carbide. Depending on the structure, full ceramic bearings have ceramic rings, rolling elements and cages; hybrid ceramic bearings have ceramic rolling elements and metal rings. They feature corrosion resistance, high temperature resistance, low friction, lightweight, non-conductive and non-magnetic properties. Suitable for special environments.

| Product Series | Material | Inner Diameter(mm) | Outer Diameter(mm) | Width(mm) | Speed(rpm) |

|---|---|---|---|---|---|

| RANUR-TC1 | Silicon Nitride(Si3N4) | 50-75 | 65-105 | 7-16 | 4.97 X1000 RPM-7.7 X1000 RPM |

| RANUR-TC2 | Zirconia(ZrO2) | 6 | 15-17 | 5-6 | 27 X1000 RPM |

| RANUR-TC3 | Silicon Carbide(SiC) | 3-5 | 10-11 | 3-4 | 31.8 X1000 RPM-36 X1000 RPM |

| RANUR-TC4 | Hybrid Ceramic | 5-70 | 14-130 | 2-29 | Suitable for medium-high speeds |

| RANUR-TC5 | Alumina(Al2O3) | 3-200 | Depends on specific model | Depends on specific model | Not suitable for higher speeds |

| RANUR-TC5 | Full Complement All Ceramic | 3-200 | Depends on specific model | Depends on specific model | Generally lower than steel bearings |

Product Performance Parameters

Ceramic bearings feature excellent properties such as high hardness, low friction coefficient, high temperature resistance, corrosion resistance, insulation and lightweight. They can operate stably in extreme environments, have long service life, are suitable for high-speed operation, and are widely used in high-precision, high-performance fields.

| Physical Performance Indicators | Parameter Value |

|---|---|

| Density | 3.2-6.0 g/cm³(40-60% lighter than steel bearings) |

| Hardness | HRA 80-92 (Far exceeds metal bearings) |

| Elastic Modulus | 280-450 GPa (High rigidity) |

| Thermal Expansion Coefficient | 3.0-10.5×10⁻⁶/°C(Low thermal deformation) |

| Thermal Conductivity | 15-120 W/(m·K) (Excellent heat dissipation) |

| Bending Strength | 500-1200 MPa |

| Compressive Strength | 2000-4000 MPa |

| Fracture Toughness | 4-8 MPa·m¹/² |

| Fatigue Limit | 2-3 times that of steel bearings |

| Service Life | 3-5 times that of steel bearings |

| Environmental Performance Indicators | Parameter Value |

|---|---|

| Operating Temperature | -200°C~+1000°C |

| Thermal Shock Stability | ΔT=300-500°C |

| High-Temperature Strength Retention Rate | Maintains 80% strength at 800°C |

| High-Temperature Creep Rate | Extremely low |

| Thermal Conductivity | Excellent heat dissipation performance |

| Corrosion Resistance | Resistant to corrosive media such as acids, alkalis and salts |

| Non-Magnetic | Completely non-magnetic, suitable for MRI and other equipment |

| Insulation | Resistivity 10¹²-10¹⁴ Ω·cm |

| Self-Lubrication | Can operate without lubrication |

| Wear Resistance | Wear rate is only 1/10 of steel bearings |

Replacing Traditional Bearings with Ceramic Bearings

With excellent high temperature resistance, corrosion resistance, low friction and high hardness, ceramic bearings can meet the needs of extreme working conditions. They also feature lightweight and self-lubricating properties, effectively improving equipment operating efficiency and service life, making them an ideal replacement for traditional metal bearings.

| Performance Indicators | Ceramic Bearings | Traditional Steel Bearings |

|---|---|---|

| Weight | Lightweight (40-60% lighter than steel) | Heavy |

| Corrosion Resistance | Extremely strong (resistant to acids, alkalis and salts) | Prone to corrosion |

| Maximum Operating Temperature | Up to 1000°C | About 250°C |

| Service Life | 3-5 times that of steel | General Service Life |

| Self-Lubricating or Not | Yes, can operate without lubrication | No, requires lubrication |

| Insulation | Completely Insulated | Conductive |

| Magnetic | Non-Magnetic | Magnetic |

Our Advantages

Choosing Rangyun Ceramic Bearings means higher speed, better hygiene and greater reliability.

Professional Technical Team

We have an R&D team of over 20 experts in materials science and mechanical engineering, focused on innovation and breakthroughs in ceramic bearing technology. All team members come from renowned universities and research institutions at home and abroad, with rich theoretical knowledge and practical experience.

Advanced Production Equipment

We have introduced the most advanced ceramic bearing production lines and testing equipment from Germany and Japan, including high-precision CNC grinding machines, isostatic presses and high-temperature sintering furnaces, ensuring that product precision and quality reach internationally leading levels.

Excellent Product Performance

Our ceramic bearings use high-purity raw materials and unique processes, featuring excellent properties such as lightweight, high temperature resistance, corrosion resistance, non-magnetic insulation, with performance far exceeding traditional metal bearings.

Customized Solutions

We provide customized products and services according to customers' special needs, offering one-stop solutions from material selection, structural design to performance optimization.

Success Cases

Rangyun Ceramic Bearings have brought outstanding performance and significant benefits to numerous customers.

Medical Device Dialysis Machine Case

Ceramic bearings for dialysis pump drives - corrosion/wear resistant, reducing maintenance and downtime

Metallurgical High-Temp Furnace Case

High-temp ceramic bearings for kiln wheels - solve lubrication failure & material softening, boosting reliability

Marine Underwater Drone Application

Marine propeller ceramic bearings - corrosion-proof, minimal maintenance, extended service life

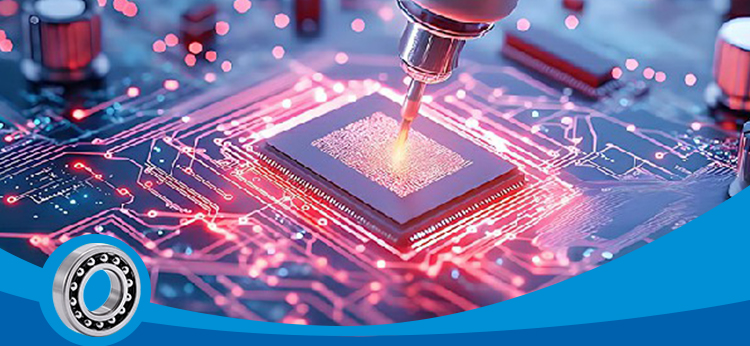

Semiconductor Cleanroom Solution

Semiconductor wafer handler & servo motor ceramic bearings - lubrication-free, ultra-wear-resistant, high-temperature capable for contamination-free operation

Food Processing Equipment Case

Food-grade ceramic bearings for conveyors & mixers - eliminate lubricant contamination, withstand washdowns, reduce replacement frequency

Petrochemical Industry Reactor Case

Reactor agitator ceramic bearings - corrosion/acid-proof, extreme wear resistance for harsh chem environments, slashing maintenance downtime