New Product Lineup

To overcome all unknowns, partial knowledge, and unpredictability,

Rangyun Technology continues to move forward, always committed to the development, design, experimentation, verification, and application of bearings under new products, new materials, and new applications, or collaborating with customers to develop, customize, produce, and validate successful new materials and new products, providing customers with the most innovative bearing solutions and products to meet and support their needs in technological innovation and product design.

Most industry applications face different technical and business challenges. Collaboration with various industries has enabled Rangyun Technology to gain experience in developing products and services required for specific industries and realize that knowledge from one industry can sometimes be successfully applied to another. We can combine the correct RANUR series engineering bearing knowledge, experience, and equipment to form a tailored solution based on your special needs and provide support throughout the entire lifecycle of your product.

Make bearing movement more scientific, make bearing acceleration more scientific, make bearing life more scientific, and break through limits in the cycle of life!

Carry out mass production and planned production of the above bearing products.

Through these high-precision testing equipment, we strictly control the production process to provide customers with more reliable and high-quality bearing products.

Future Bearing Technologies

Smart Bearings

Self-diagnosis and predictive maintenance: Predict faults through data analysis, reducing downtime.

Magnetic Levitation Bearings

Active and passive control: Active control adjusts through electromagnetic force, while passive control relies on permanent magnets.

Air Bearings

Pollution-free and low vibration: Oil-free lubrication reduces pollution and ensures smooth operation.

Superconducting Bearings

Low Energy & Stability: Ensures efficiency and reliability for precision instruments and energy sector.

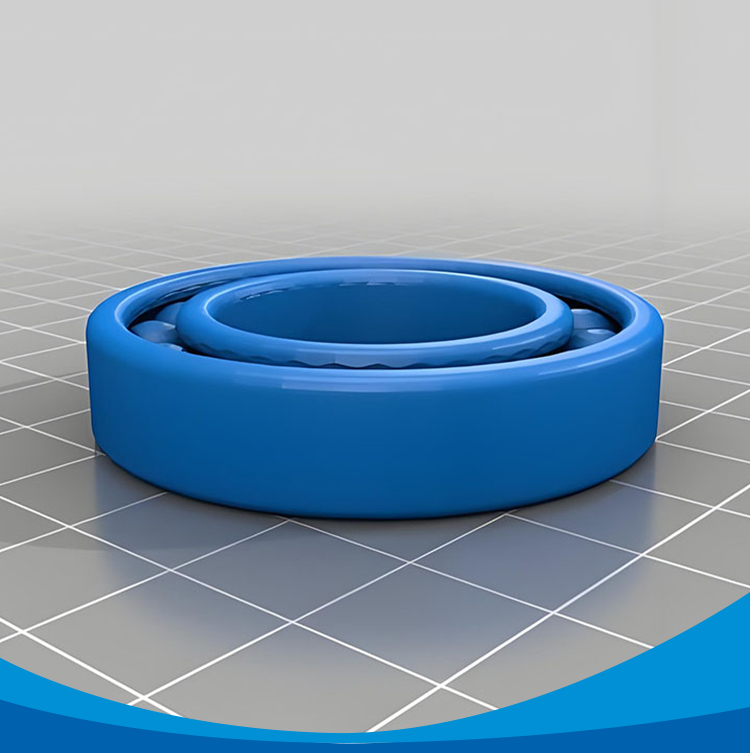

3D Printed Bearings

Rapid prototyping and lightweight: Accelerates prototype development, reduces material usage, and lowers weight.

Nano Bearings

Microstructure optimization: Optimizes microstructure through nanotechnology to improve performance.