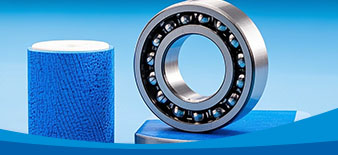

Advanced Equipment and Precision Testing

As a professional bearing manufacturer, we use high-precision, efficient equipment, including CNC lathes, grinding machines, and automated production lines, to ensure quality and efficiency. We also employ advanced tools like ultrasonic cleaners, spray granulators, and nitriding furnaces to meet material and heat treatment needs, expanding our processing capabilities.

We use advanced international measurement, material, and bearing testing equipment, along with domestic precision instruments like CMMs, microhardness testers, metallographic microscopes, and X-ray stress testers

Quality Assurance System

The company has a dedicated quality assurance team overseeing quality control throughout the production process—covering incoming materials, manufacturing, and outgoing products—to ensure standards compliance and precision reserves.

Safety & Expertise

We hold certifications for safety production and management systems (ISO18001, ISO9001, ISO14001) and prioritize innovation and IP protection. Our expert team, led by a materials science PhD, includes industry leaders and patent holders, driving advancements in bearing technology and standards.

Bearing Support Services

We offer technical support for RANUR and ROHOR series, including bearing selection, materials, installation tools, repair, maintenance, lubrication, brand protection, testing, and life evaluation. Our goal is to provide efficient, scientific bearing solutions, advancing the industry.