Industrial Plastic Bearings – Corrosion Resistant

Providing you with the most reliable plastic bearing solutions, featuring corrosion resistance, self-lubrication, and maintenance-free properties

Plastic Bearing Product Parameters

Plastic bearings are mainly made of high-performance engineering plastics, including POM, PA, PP, PE, UPE, PEEK, PI, PTFE, PVDF, etc. They feature light weight, corrosion resistance, self-lubrication, low noise, and insulation, making them suitable for special environments such as food, medical, chemical, and electronics industries.

| Product Series | Material | Inner Diameter(mm) | Outer Diameter(mm) | Width(mm) | Operating Temperature |

|---|---|---|---|---|---|

| RANUR-PL1 | POM/PA | 3-200 | 8-300 | 3-80 | -40°C-+120°C |

| RANUR-PL2 | PP/PE/UPE | 5-150 | 10-200 | 5-50 | -50°C-+80°C |

| RANUR-PL3 | PEEK/PI | 5-120 | 10-180 | 5-40 | -100°C-+260°C |

| RANUR-PL4 | PTFE/PVDF | 3-100 | 8-150 | 3-30 | -200°C-+200°C |

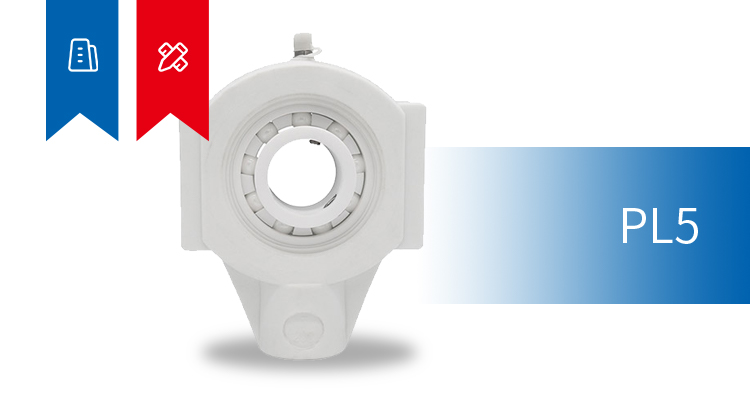

| RANUR-PL5 | Plastic Bearing Housing | 10-200 | Depending on the Specific Model | Depending on the Specific Model | -40°C-+120°C |

Plastic Bearing Performance Parameters

Plastic bearings feature excellent properties such as light weight, corrosion resistance, self-lubrication, insulation, and low noise. They can operate stably in special environments like humidity and corrosion without maintenance, and are widely used in food, medical, chemical, and other fields.

| Physical Performance Indicators | Parameter Value |

|---|---|

| Density | 1.0-1.5 g/cm³ (60-80% lighter than steel bearings) |

| Hardness | HRR 60-120(Lower than metal bearings) |

| Elastic Modulus | 1-4 GPa(Low rigidity) |

| Thermal Expansion Coefficient | 50-150×10⁻⁶/°C(High thermal deformation) |

| Thermal Conductivity | 0.1-0.5 W/(m·K)(Low thermal conductivity) |

| Tensile Strength | 30-200 MPa |

| Compressive Strength | 50-300 MPa |

| Friction Coefficient | 0.05-0.3 (Self-lubricating) |

| Water Absorption | 0.01-3% (24 hours) |

| Service Life | Comparable to metal bearings under suitable conditions |

| Environmental Performance Indicators | Parameter Value |

|---|---|

| Operating Temperature | -200°C-+260°C(Depending on the material) |

| Chemical Resistance | (Resistant to acids, alkalis, salts, and various organic solvents) |

| Weather Resistance | Excellent UV and aging resistance |

| Self-Lubrication | Most plastic bearings can operate without lubrication |

| Insulation | Resistivity 10¹⁴-10¹⁶ Ω·cm |

| Non-Magnetic | Completely non-magnetic |

| Food-Grade Certification | Some materials are FDA-certified |

| Noise Level | 10-20dB lower than metal bearings |

| Wear Resistance | Special formulations can improve wear resistance |

| Maintenance-Free | Most applications require no lubrication maintenance |

Replacing Traditional Bearings with Plastic Bearings

Plastic bearings can meet the needs of special industries such as food, medical, and chemical due to their excellent corrosion resistance, self-lubrication, and insulation properties. They also feature light weight, low noise, and maintenance-free characteristics, effectively reducing equipment operating costs and maintenance difficulties.

| Performance Indicators | Plastic Bearings | Traditional Steel Bearings |

|---|---|---|

| Weight | Extremely light (60-80% lighter than steel) | Heavy |

| Corrosion Resistance | Extremely strong (resistant to acids, alkalis, salts, and various solvents) | Prone to corrosion |

| Self-Lubrication | Most can operate without lubrication | Requires lubrication |

| Insulation | Completely insulated | Conductive |

| Noise Level | Low noise (10-20dB lower) | Higher noise |

| Food-Grade Certification | Some materials are FDA-certified | Generally none |

| Maintenance Requirements | Mostly maintenance-free | Requires regular lubrication |

Our Advantages

Choosing Rangyun Plastic Bearings is more economical, environmentally friendly, and reliable.

Professional Plastic Bearing R&D Team

Our technical team has over 15 years of experience in plastic bearing R&D, focusing on the application research of engineering plastics in the bearing field, and can provide optimal material solutions for different working conditions.

Advanced Injection Molding Process

Introducing advanced precision injection molding equipment and processing centers from Germany and Japan to ensure dimensional accuracy and performance stability of plastic bearings, with tolerances up to IT5 grade.

Comprehensive Material Solutions

Providing various engineering plastic bearings such as POM, PA, PP, PE, UPE, PEEK, PI, PTFE, PVDF to meet different working condition requirements.

Strict Quality Control System

Implementing full-process quality control from raw material entry to finished product delivery to ensure every plastic bearing meets technical requirements.

Success Cases

Rangyun Plastic Bearings have solved bearing problems under special working conditions for numerous industry customers.

Food Processing Equipment Case

Provided POM plastic bearings for a large food enterprise’s conveying equipment, solving the lubrication pollution issue of traditional bearings, and ensuring food safety with FDA certification.

Chemical Industry Pump Bearing Case

Provided PVDF plastic bearings for a chemical enterprise’s acid and alkali liquid transfer pumps, resistant to strong acid and alkali corrosion, with a service life three times longer than stainless steel bearings.

Medical Device Bearing Case

Provided PEEK plastic bearings for a medical device company, meeting high-temperature steam sterilization requirements without producing metal ion pollution.

Water Treatment Equipment Case

Provided UPE plastic bearings for a sewage treatment plant, resistant to sewage corrosion, self-lubricating and maintenance-free, significantly reducing maintenance costs.

Electronic Insulated Bearing Case

Provided PI plastic bearings for an electronic equipment manufacturer, completely insulated to avoid current corrosion and improve equipment reliability.

Packaging Machine Quiet Bearing Solution

Provided PTFE plastic bearings for a packaging machinery enterprise, reducing operating noise by 15dB and improving the working environment.