About Experimentation

Bearing Experiment Work Content

1. Bearing structure analysis: Observe the appearance of the bearing to understand its structural composition and compare the structural characteristics of different types of bearings.

2. Bearing performance evaluation: Test aspects such as friction torque, temperature, and durability to assess the quality and performance of the bearing.

3. Bearing installation and removal: Learn installation methods such as pressing, fitting, and heating, and practice actual operation.

4. Bearing adjustment: Understand the concept and adjustment method of bearing clearance, learn the measurement method of bearing clearance, and practice adjustment.

5. Bearing lubrication and sealing: Understand the purpose and types of bearing lubrication, master the selection method of bearing lubricants, and observe the structure and function of seals.

6. Bearing failure analysis: Analyze the causes of bearing failure, such as wear, fatigue, and corrosion, and understand preventive measures.

Common instruments for bearing tests

1. Bearing tester: Such as rolling bearing fault detector and vibration analyzer, used to monitor bearing vibration, temperature and other parameters in real time to detect signs of trouble.

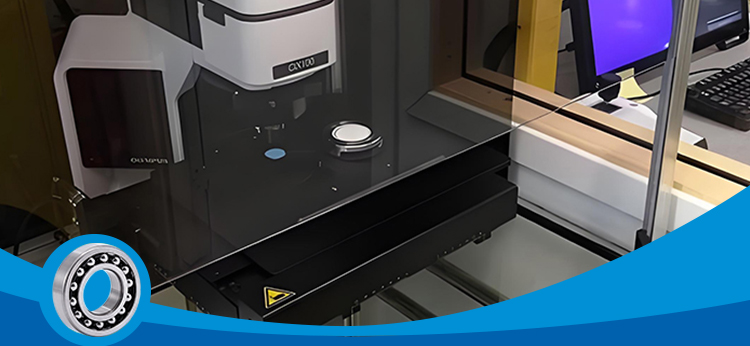

2. Coordinate measuring machine: Used to measure the size and shape accuracy of bearings precisely.

3. Length measuring instrument: Used to measure dimensional parameters such as bearing length.

4. Hommel roundness measuring instrument: Used to detect roundness errors of bearings.

5. Microhardness tester: Used to measure the hardness of bearing materials.

6. Metallographic microscope: Used to observe the microstructure and defects of bearing materials.

Development direction of bearing tests

1. Intelligence: With the continuous advancement of artificial intelligence and Internet of Things technology, intelligent bearing testers will become the future development trend. The application of sensor technology enables bearing testers to achieve real-time data acquisition and analysis, improving the accuracy and efficiency of monitoring.

2. Customization: Customized design according to the needs of different industries and specific equipment to meet the needs of different industries for precise monitoring and analysis of bearing performance parameters.

3. High precision: With the continuous development of industrial manufacturing technology, the requirements for the accuracy and speed of bearing performance parameter detection are also increasing. Future bearing testers will focus more on improving testing accuracy and speed to meet the needs of efficient production.

4. Data analysis: Combined with big data technology, bearing testers can achieve data storage and sharing, remote monitoring and diagnosis on a global scale, and provide more convenient and efficient ways for equipment maintenance and management.

In summary, the cutting-edge experimental content, instruments and development direction of the bearing industry reflect a high degree of concern for the quality, performance and reliability of bearings, as well as the development trends of intelligence, customization, high precision and data analysis.

Bearing-related test items

Performance test (rotation accuracy test, friction torque test, speed test...)

Durability test (fatigue life test, accelerated life test...)

Load test (static load test, dynamic load test...)

Environmental adaptability test (temperature test, humidity test, corrosion test...)

Vibration and noise test

Sealing performance test

Lubrication test (lubricant performance test, lubrication effect test...)

Material test (material composition analysis, metallographic analysis...)

Cleanliness test

Packaging and transportation test

Special application test (high-speed test, low-temperature test...)

Data analysis and reporting (data recording and analysis, report writing...)