Factory Tour

Welcome to our smart factory. We provide bearings in various materials, manufacturing processes, designs, and coatings. Our product range includes: full-series ceramic bearings, plastic bearings, high-temperature bearings, insulated bearings, stainless steel bearings, bearing steel bearings, Hastelloy bearings, solid-oil lubricated bearings, and bearings with special coatings, totaling 9 major categories and 39 sub-categories. We collaborate with customers to develop, customize, and validate new materials and products, and mass-produce these bearings.

We produce over 8 million pieces annually. Our team of 80 members, including 15 technical experts, continuously innovates in our 500-sq-m R&D center. Our 40,000-sq-m factory reflects our quality commitment. Using advanced international processes, we craft each product to ensure it stands the test of time.We offer long-term, reliable solutions and services for your enterprise and assets in various operating conditions, including hygienic, dusty, vacuum, high-temperature, clean, corrosive, non-magnetic, and maintenance-free environments.

Our dedication and efforts have made us a trusted partner, continuously driving product excellence and innovation, and leading new industry trends.

Our production

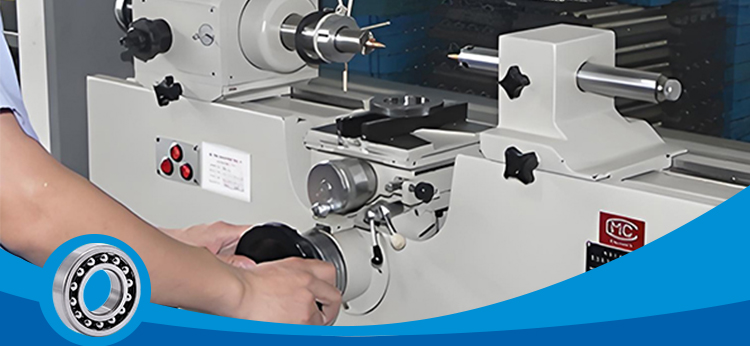

Our production is organized by senior managers with industry experience, operated by a team of professional technicians led by senior technicians honored with the National Model Worker title, and processed by specialized CNC production lines to fully ensure processing quality.

Advanced equipment

High-precision CNC vertical lathes, single-column fixed-beam CNC vertical lathes, CNC high-speed hobbing machines, CNC moving-table vertical lathes, CNC vertical compound grinders, CNC fully automatic grinding lines, CNC fully automatic heat treatment lines, CNC fully automatic assembly lines, double-channel ultrasonic cleaners, bearing matching instruments, grease-filling and cover-pressing machines, closed-spray granulators, vertical circulating stirrers, nitriding reaction furnaces, laser engraving machines, cold isostatic presses, gas-pressure sintering furnaces, hot isostatic pressing furnaces, hot isostatic presses, vacuum sintering injection molding machines,

Quality assurance system

Our company has established a quality assurance team comprising design, process, inspection, and production personnel. We've developed effective quality solutions for continuous improvement. We control the entire bearing production process with incoming quality control (IQC), in-process quality control (PQC), and outgoing quality control (OQC). Our extensive range of imported bearing testing equipment ensures effective quality control, enabling our products to not only meet standard requirements but also maintain a precision reserve.

Bearing-related production processes

Raw material inspection (chemical composition analysis, metallographic structure inspection...)

Post-heat treatment inspection (hardness testing, deformation testing, surface decarburization layer testing...)

Machining stage inspection (size accuracy, tolerance, geometric tolerance...)

Assembly process inspection (clearance testing, cleanliness testing, lubricant coating testing...)

Dynamic performance testing (rotation accuracy testing, vibration and noise testing...)

Sealing performance testing (dust/water resistance testing, lubricant leakage testing...)

Life and durability testing (accelerated life testing, fatigue testing...)

Appearance and packaging inspection (surface defect inspection, rust prevention verification, packaging integrity...)