Provide external bearing testing services

More Testing Services

Professional bearing testing to ensure accuracy, performance, quality, and durability.

Dimensional Accuracy Testing

ID/OD/W: Ensure compliance GP check: Measure shape errors

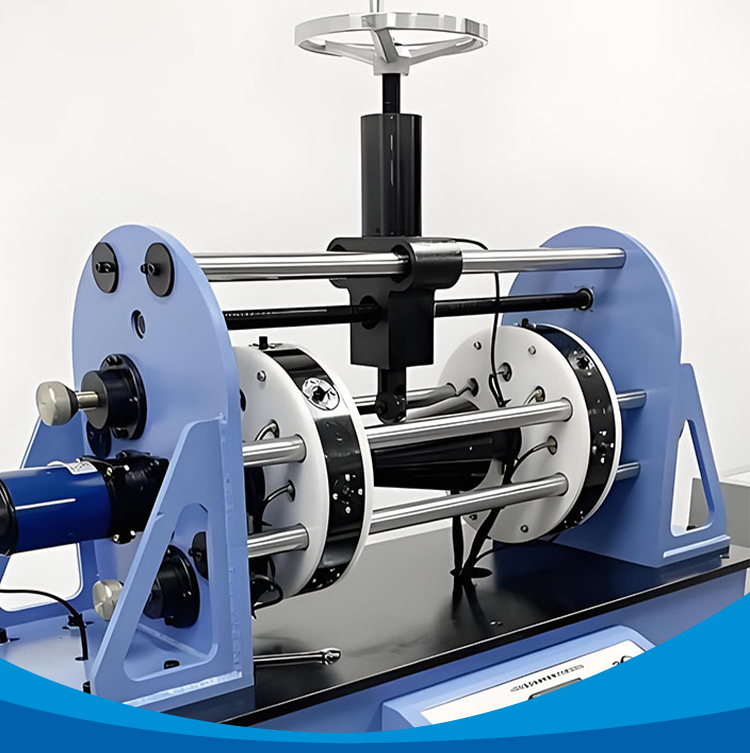

Rotational Performance Testing

Rotation: Check if the bearing rotates smoothly. Vibration: Evaluate amplitude and noise Precision: Measure radial and axial runout.

Clearance Testing

Radial clearance: Measure gap Axial clearance: Measure gap

Material Properties Testing

Hardness test: Check hardness Metallography: Assess material structure Wear test: Assess wear resistance

Surface Quality Testing

Surface Inspection: Measure the smoothness of the bearing’s working surface. Visual Inspection: Check for cracks and defects on the bearing surface.

Sealing Performance Testing

Sealing Performance: Test the dust and water resistance of the bearing. Lubrication Inspection: Check the type, amount, and distribution of lubricant.

Load Performance Testing

Static load test: Assess capacity Dynamic load test: Test durability Fatigue test: Evaluate fatigue life

Special environment test

High/low temperature test: Assess performance in extreme temperatures Corrosion test: Test resistance to corrosion

Assembly Accuracy Testing

Fit clearance: Check bearing and shaft/housing fit Fit clearance: Check bearing and shaft/housing fit

Certification testing

Industry standard compliance: Ensure bearings meet standards. Customized testing: Offer tests based on customer needs.

Reports and Recommendations

Report: Detailed results and analysis. Improvements: Suggestions for bearing design, production, or use.

We Can Be Your Solution

Rangyun Technology keeps moving forward. We are always committed to the development, design, experimentation, validation, and application of bearings for new products, materials, and applications, just to provide customers with the most innovative bearing solutions and products.

Rangyun Technology always adheres to the principles of persistence, integrity, and innovation, focusing on how to make bearing movement more scientific, how to accelerate bearings more scientifically, and how to extend bearing life more scientifically. We break through limits in the cycle of life, aiming to overcome all unknowns, uncertainties, and unpredictables.