Semiconductor Ceramic Bearing Solutions

Providing high-performance bearings for high-cleanliness, high-precision semiconductor manufacturing equipment

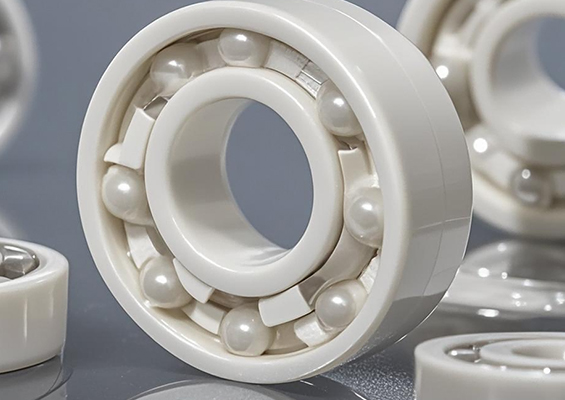

Semiconductor Industry and Ceramic Bearings

Semiconductor manufacturing is the core of today’s technology industry, with extremely high demands on equipment precision, reliability, and cleanliness. Ceramic bearings play an irreplaceable role in this field.

Special Requirements of Semiconductor Manufacturing

Semiconductor manufacturing must be carried out in ultra-clean environments, where even the smallest particle contamination can cause chip defects. At the same time, the corrosive chemicals and high-temperature environments used in processes place extremely high demands on equipment components.

Key Role of Ceramic Bearings

With their superior performance, ceramic bearings are the ideal choice for semiconductor equipment: non-magnetic, corrosion-resistant, low thermal expansion coefficient, high hardness, and excellent insulation properties, perfectly meeting the demanding requirements of semiconductor manufacturing environments.

Key Performance Data of Semiconductor Ceramic Bearings

| Performance Indicators | Silicon Nitride (Si₃N₄) Ceramic Bearings | Zirconia (ZrO₂) Ceramic Bearings | Steel bearing | Impact on Semiconductor Processes |

|---|---|---|---|---|

| Steel bearing(g/cm³) | 3.2-3.3 | 5.7-6.0 | 7.8-7.9 | Lower inertia, faster response |

| Hardness (HV) | 1400-1800 | 1200-1400 | 700-800 | Higher wear resistance, longer life |

| Thermal expansion (10⁻⁶/K) | 3.0-3.2 | 10.0-11.0 | 11.0-13.0 | Stable at high temperatures |

| Corrosion Resistance | Excellent (Acid/alkali resistant) | Excellent (Acid/alkali resistant) | special treatment | Corrosion-proof, clean |

| Particle Generation | <0.1mg/1000h | <0.1mg/1000h | 1–5mg/1000h | Class 1 cleanroom compliant |

| Max temp(°C) | 800 | 600 | 150-200 | For high-temp equipment |

| Magnetic Permeability | Non-magnetic | Non-magnetic | Magnetic | No interference with electronics |

Application Areas

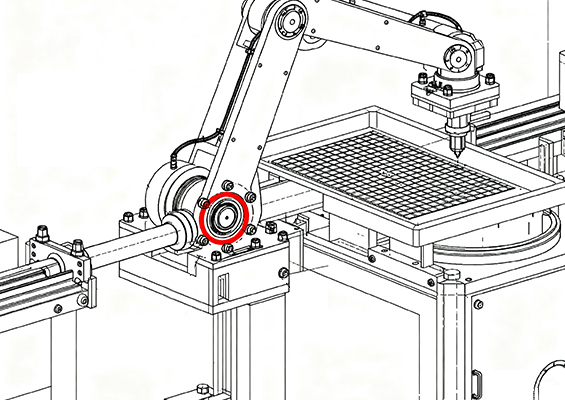

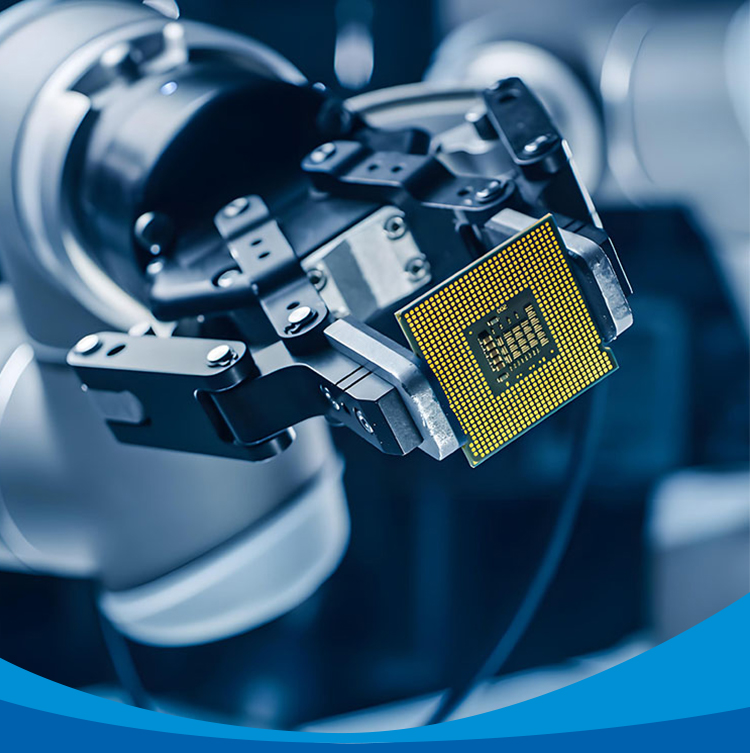

Ceramic bearings are widely used in multiple key components of semiconductor manufacturing equipment, including vacuum pumps, robotic arms, wafer transfer systems, lithography machines, CVD equipment, etching machines, and ion implanters. As semiconductor process technology continues to advance, the performance requirements for ceramic bearings also continue to increase.

Technology Development Trends

As semiconductor manufacturing moves toward smaller process nodes (e.g., 3nm, 2nm), the requirements for ceramic bearings continue to rise. Future trends include: higher speeds (>30,000 rpm), lower particle generation, better temperature stability, and longer service life.

Applications in Semiconductor Equipment

Our ceramic bearings are widely applied in key parts of semiconductor manufacturing equipment, ensuring high performance under harsh conditions.

| Equipment Name | Equipment Image | Application Location | Performance Requirements | Reason for Ceramic Bearing Feasibility |

|---|---|---|---|---|

| Vacuum Pump Systems |  |

Main shaft bearings for dry vacuum pumps and turbo molecular pumps | High speed, low vibration, and corrosion resistance to ensure stability of the vacuum environment | Ceramic materials have low density and high elastic modulus, enabling higher speeds; excellent corrosion resistance can resist corrosive gases in vacuum environments |

| Wafer Handling Robots人 |  |

Robot arm joints and transmission systems | High precision positioning and clean operation to prevent wafer contamination | Ceramic bearings generate almost no particles, meeting ultra-high cleanliness requirements; low friction coefficient ensures precise positioning and smooth operation |

| Lithography Machines |  |

Precision stage and lens positioning systems | Nanometer-level precision and non-magnetic interference to improve lithography resolution | Ceramic bearings are completely non-magnetic, avoiding interference with precision electronic systems; high hardness and stability ensure nanometer-level positioning accuracy |

| CVD/PVD Equipment |  |

Rotating mechanisms and transmission systems inside high-temperature reaction chambers | Resistance to high temperatures and corrosive gas environments | Ceramic materials have excellent high-temperature stability and corrosion resistance, allowing long-term stable operation in high-temperature corrosive gas environments |

| Etching Equipment |  |

Wafer clamping and rotating mechanisms | Resistance to strong corrosive chemicals, extending equipment life | Ceramic bearings have extremely strong corrosion resistance to most acids, alkalis, and solvents, far exceeding traditional metal bearings |

| Ion Implanters |  |

Beam control and target disk drive systems | Non-magnetic and high insulation properties to ensure ion beam accuracy | The insulating properties of ceramic bearings prevent charge accumulation and discharge; non-magnetic properties ensure the ion beam is not disturbed |

| Chemical Mechanical Polishing (CMP) |  |

Polishing pad drive and wafer clamping systems | High wear resistance and chemical stability | Ceramic materials have high hardness and excellent wear resistance, while also resisting chemical corrosion from polishing slurries |

| Inspection & Metrology Equipment |  |

Transmission systems for precision measuring instruments and probe stations | Ensuring measurement accuracy and repeatability | The low coefficient of thermal expansion and dimensional stability of ceramic bearings maintain high measurement accuracy even in varying temperature environments |

Rangyun Bearing Product Advantages

Our ceramic bearings provide unique performance advantages for semiconductor manufacturing

Ultra-High Cleanliness

Extremely low particle generation and outgassing characteristics meet Class 1 semiconductor cleanroom requirements, preventing wafer contamination. Particle generation is less than 0.1mg per 1000 hours of operation

Excellent Corrosion Resistance

Capable of resisting various strong acids, alkalis, and corrosive gases used in semiconductor processes, extending equipment life. Exhibits excellent stability in most acidic and alkaline environments

High-Temperature Stability

Maintains dimensional stability and mechanical properties in high-temperature environments, suitable for high-temperature process equipment like CVD and diffusion furnaces. Operating temperature can reach 800°C (silicon nitride material)

Non-Magnetic and Insulating Properties

Completely non-magnetic and highly insulating, does not interfere with precision electronic equipment and measuring instruments during semiconductor manufacturing. Resistivity can reach above 10¹⁴ Ω·cm